Key takeaways:

Staying safe on the job is crucial for plumbers, and these ten tips can help create a safer, more productive workday for your crew.

- Develop and enforce a health and safety policy. Outline clear emergency procedures, reporting steps, and jobsite rules to guide your team and ensure compliance with local regulations.

- Create comprehensive job orders. Include all necessary job details, hazard information, and codes to help plumbers identify potential risks before arriving at the site.

- Prioritize health and safety training. Ensure every team member completes initial and ongoing safety training, covering equipment handling, PPE usage, and hazard awareness.

- Maintain detailed safety data sheets (SDS) and equipment inspections. Keep SDS accessible for all chemicals and regularly inspect and document the condition of tools and equipment to prevent injuries.

- Invest in and use personal protective equipment (PPE). Equip your team with appropriate gear such as gloves, eyewear, boots, masks, and other protective items to guard against site hazards.

- Secure proper insurance coverage. Protect your business and employees with relevant insurance types including liability, property, and workers’ compensation policies.

- Utilize safety checklists and ergonomic practices. Implement health and safety checklists for every job and encourage ergonomic tools and techniques to reduce strain and prevent injuries.

- Encourage open communication around safety. Foster a culture where team members feel comfortable reporting hazards or unsafe conditions as soon as they arise.

- Understand and mitigate common plumbing hazards. Be vigilant about risks such as hazardous substances, slips, electric shock, burns, noise, cuts, and musculoskeletal injuries by applying prevention best practices on every site.

Want more tips to keep your plumbing business safe and successful? Sign up for the Jobber Newsletter.

Plumbing is hands-on work, and safety plays a key role in getting every job done right. When you understand common jobsite risks and prepare your team with the right processes, you can reduce injuries and keep work moving smoothly.

In this guide, we’re sharing the top ten safety tips for plumbing crews to follow—plus a list of common hazards and best practices to keep every jobsite safe.

10 plumbing safety tips:

-

Build a health and safety policy

-

Create detailed job orders

-

Health and safety training

-

Use safety data sheets (SDS)

-

Inspect your plumbing equipment

-

Invest in personal protective equipment (PPE)

-

Get the right insurance

-

Create health and safety checklists

-

Use ergonomic practices to prevent injuries

-

Encourage open communication about safety concerns

1. Build a health and safety policy

Creating a health and safety policy for your plumbing company is an important step in setting up your broader workplace safety program.

A reliable health and safety policy should include:

- First aid and plumbing emergency procedures – How to respond quickly to injuries and urgent situations

- Accident report and investigation steps – What to document and review after an incident

- General site rules to create a safer work environment – Clear expectations for everyday jobsite safety

- An emergency fire or medical response plan – Who to call and what to do in a crisis

Pro Tip: Check with your local and state government to see if a health and safety policy is required and what specifically needs to be included.

2. Create detailed job orders

Clear, detailed work orders play an important role in jobsite safety. They should include any information that helps plumbers understand potential hazards and work more safely on site, like:

- The plumbing issue or job to be done

- Relevant plumbing or building codes

- Images of the work environment

- Any potential site hazards to be aware of

Use Jobber’s job management software to capture all the details your team needs to get the job done safely.

3. Health and safety training

Require all new employees to complete health and safety training before starting work, and schedule annual refreshers to maintain consistent, up-to-date safety practices across your team.

You can provide this safety training for your team on your own, through a third-party workforce service, or even a government provider, like OSHA in the United States.

Use this training to cover plumbing safety topics such as:

- OSHA (U.S.) or WHMIS training (Canada)

- Hazard awareness

- Proper equipment handling

- Personal protective equipment

READ MORE: Top 4 ways to get your employees on board with safety procedures

4. Use safety data sheets (SDS)

Safety data sheets help you understand the health hazards of the chemicals you’re using and what PPE you’ll need to safely handle the substances.

Make sure these are always readily available to plumbers in their work van or tool bag.

5. Inspect your plumbing equipment

Keeping your plumbing tools in tip-top condition with regular inspection can help you avoid accidents or injuries caused by unsafe equipment.

This involves more than just fuel top-ups for your work van. Here are a few steps for effective inspection of your plumbing equipment:

- Create an inspection schedule: For consistency, create a schedule to inspect your equipment daily, weekly, or monthly. Regular inspections help you see the wear and tear early on, so you can buy replacements or make repairs before you get to the job site.

- Check for damage: During each inspection, check for any signs of equipment damage. Look for cracks, rust, frayed cords, and loose parts. Even a tiny bit of damage can pose safety risks.

- Test for functionality and accuracy: Test power tools to confirm they run smoothly without unusual noises or vibrations. For equipment that requires precision (such as pressure gauges and measuring tools), verify their accuracy and calibration. Bad readings could lead to ineffective installations and compromise plumbing safety.

- Clean your tools: Clean and maintain your tools to prevent buildup of dirt and grime, which could impact how your equipment functions. Follow the manufacturer’s maintenance guidelines—including lubrication and sharpening—to keep your tools in tip-top shape.

- Document everything: Keep records of all inspections and maintenance. This helps with accountability and tracks the condition of your equipment over time. It could also be valuable later if you need to troubleshoot again.

6. Invest in personal protective equipment (PPE)

Make sure your team has the right safety gear (like gloves, safety glasses, and work boots) to stay safe against a potential safety hazard.

To protect against the spread of bacteria and viruses from working around raw sewage, have sanitizer and disinfectant wipes readily available to clean your hands and equipment.

Personal protective equipment you need for every job

Protective eyewear

Safety glasses can help protect your eyes from flying debris and hot water or chemical splashes. Wear eye protection when you’re using harsh chemicals or power tools.

Pro Tip: Prescription glasses and safety glasses are not created equal when it comes to safety on a job site. If you wear prescription glasses, find a pair of protective glasses that fit comfortably over your frames.

Plumbing gloves

Your hands are one of your most valuable plumbing tools, which is why it’s important to protect them from cuts, burns, chemicals, biohazards, and more.

You’ll want to invest in different types of plumbing gloves like nitrile and leather to protect your hands from every hazard.

Non-slip safety boots

Protect your feet from heavy falling objects and avoid slipping on wet surfaces with a good pair of safety boots. To keep safe and comfortable all day long, look for boots that have these features:

- Waterproof

- Oil and slip-resistant

- Steel toe or steel cap

- Electrical hazard protection

- Lightweight and comfortable

Masks

Wearing a mask on the job can help protect your lungs from dangerous elements on the worksite. When working with potentially toxic substances like mold or asbestos, it’s best to wear a respirator mask for proper filtration.

Dust masks, on the other hand, will protect you from non-toxic dust caused by cutting pipes, or dirty work environments.

Additionally, wearing a face mask in a customer’s home can help protect you against potential airborne viruses.

Face shields

Similar to masks, face shields provide additional protection for your face against splashes, flying debris, and hazardous substances. Use them with safety glasses or goggles for even better face protection.

Knee pads

Knee pads give you some cushioning and support when kneeling on hard surfaces. Look for durable pads with adjustable straps for a comfortable fit.

Coveralls

Coveralls protect your skin and clothing from just about everything you might encounter on the job site. Choose coveralls that are made from durable, flame-resistant materials. Make sure they’re easy to move around in before you spend an entire day uncomfortable.

Earplugs

Sharp and loud noises on the job site can cause long-term damage to your ears. Use earplugs when working with loud machinery or on noisy worksites, like construction zones.

7. Get the right insurance

Protect your plumbers and your company with the right plumbing insurance coverage.

At the very least, you’ll want general liability insurance to protect against claims related to injury and property damage. You may also want:

- Professional liability insurance

- Business property insurance

- Workers’ compensation insurance

- Commercial auto insurance

Talk to your insurance company to figure out which policies are best for your business.

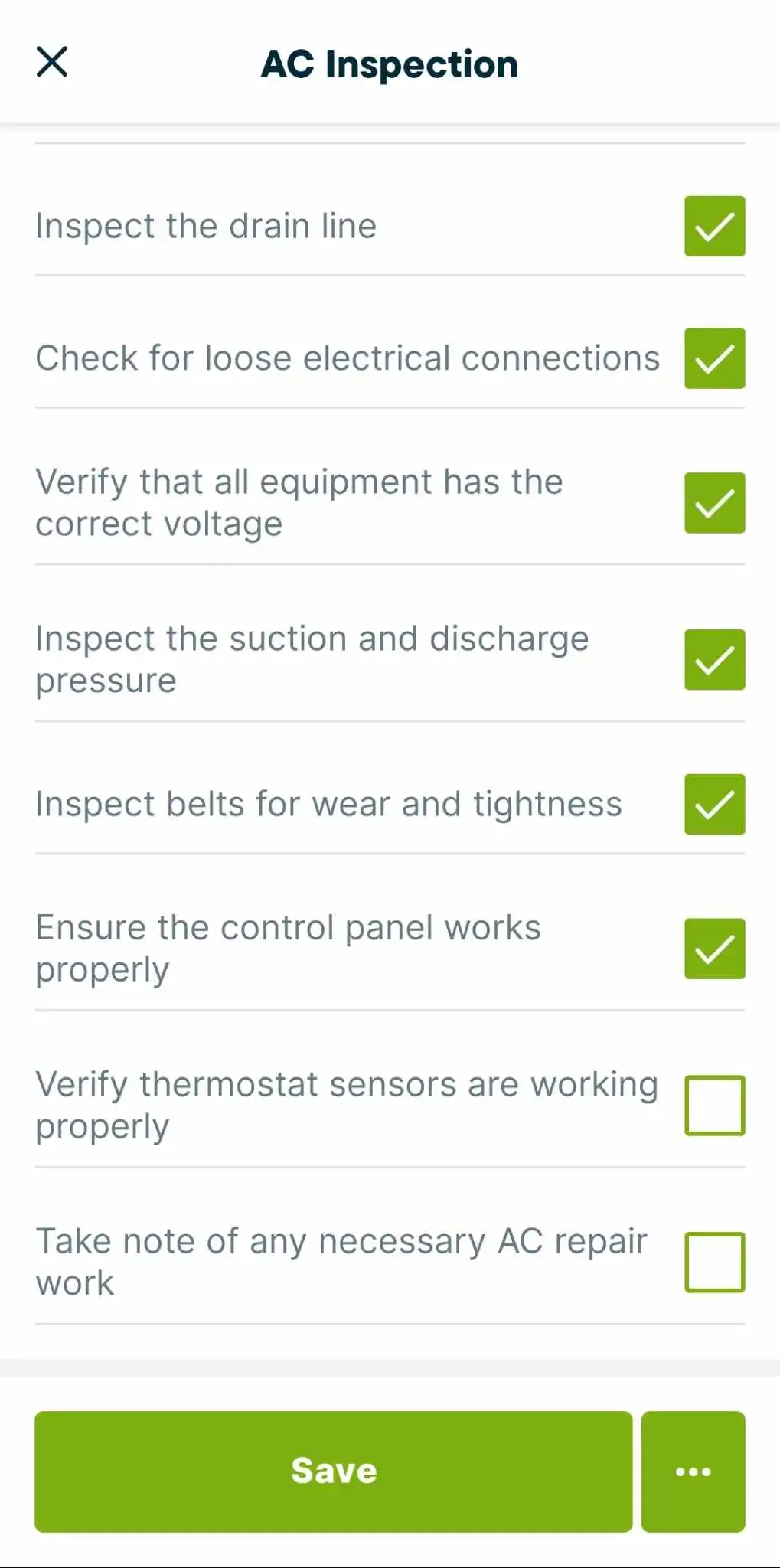

8. Create health and safety checklists

A safety checklist can help your plumbers identify hazards on the job site and prevent injuries and other health risks.

Here’s what a custom safety checklist looks like in Jobber:

Jobber’s field service forms let you build and attach safety checklists with required fields and checkboxes for each job type, helping your team follow the right safety steps on every site.

9. Use ergonomic practices to prevent injuries

Ergonomic practices help you minimize physical strain and prevent injuries from heavy lifting, awkward postures, and repetitive tasks. Here’s how to improve the well-being of your team:

Lifting techniques

A common cause of strain in plumbing is lifting heavy objects like pipes, fixtures, and your own equipment. Plumbing professionals should:

- Evaluate the weight and size of the object before lifting it. If it’s too heavy, get assistance or use a lifting device.

- Bend at the knees and keep your back straight when lifting. “Lift with your legs,” as they say. And not with your back.

- Hold the object close to your body to maintain balance.

- Turn your whole body instead of twisting it when moving an object. Twisting can increase the risk of back injuries.

Tools to reduce physical strain

Using the right tools can help you perform plumbing services more efficiently and with less physical effort. Consider the following:

- Pipe stands and supports can hold pipes in place, reducing the need to manually support them.

- Rolling carts help you transport heavy tools and plumbing fixtures around the job site, instead of carrying them by hand.

- Power tools, such as electric pipe cutters and drills, reduce the need for repetitive manual efforts.

- Workbenches that can be adjusted to different heights can help you work at a comfortable level.

Regular breaks and stretching

Short, regular breaks and simple stretches help reduce muscle strain, prevent fatigue, and keep plumbers focused on the job.

When it comes to plumbing safety, creating a safe working environment requires you to know the risks and be prepared for anything. You can make identifying risks even easier with Jobber’s custom safety checklists.

READ MORE: What is a Job Hazard Analysis checklist?

10. Encourage open communication about safety concerns

Open communication helps prevent accidents before they happen. In your role as business owner, set an expectation that technicians should speak up as soon as they notice a safety issue.

Invite your team to let you know about any unsafe conditions or potential hazards on a job site.

Early reporting ensures that problems don’t turn into injuries, property damage, or job delays. When your team trusts you and knows their concerns will be taken seriously, they’re more likely to stay alert, follow safety procedures, and look out for one another.

Common plumbing hazards and risks

Every plumbing service or repair comes with potential safety hazards. Knowing the risks can help you avoid plumbing accidents and take the right safety measures for every job.

Here are a few common plumbing risks and potential hazards you may face on the job:

1. Exposure to hazardous substances

Professional plumbers often encounter hazardous materials and biohazardous substances such as:

- Asbestos

- Chemicals

- Lead

- Mold (from water damage)

- Raw sewage

- Gas leaks

- Sulfur dioxide

Exposure to these materials can cause serious health issues if you don’t take precautions. Use appropriate protective gear (such as gloves and masks) and make sure you have proper ventilation to minimize any exposure.

How you can prevent or reduce hazardous substances risk:

- Identify potential hazards before starting the job.

- Use appropriate protective gear (gloves, masks, and respirators) when needed.

- Ensure proper ventilation in enclosed or poorly ventilated areas.

- Follow safe handling and disposal guidelines for hazardous materials to reduce exposure.

2. Slips, trips, and falls

Wet working conditions from leaks and other plumbing activities can lead to slips, trips, and falls. These accidents are some of the most common plumbing safety hazards.

Slips and falls can cause injuries ranging from minor bruises to serious fractures that sideline your technicians. They can also damage client property or result in downtime, insurance claims, and troublesome costs.

How to prevent or reduce slips and falls:

- Always keep your work area clean and dry

- Wear non-slip footwear designed for wet or uneven surfaces

- Place caution or warning signs near wet areas when available

- Address leaks promptly to prevent water from spreading across the work site

3. Hearing loss from loud noises

Loud noises from banging tools, pipes, or plumbing machinery can contribute to hearing loss over time.

Repeated exposure to high noise levels can cause permanent hearing damage for technicians. It can also make it harder to communicate on the job, increasing the risk of mistakes or accidents.

How you can reduce danger from loud noises:

- Wear earplugs or earmuffs when working with noisy equipment

- Monitor noise levels on the job site when possible

- Limit prolonged exposure by taking breaks away from loud environments

- Implement hazard controls to reduce unnecessary noise where you can

4. Cuts and fractures

Working with plumbing equipment and power tools can result in cuts, fractures, or broken bones.

These injuries can take technicians off the job site instantly. Mishandled tools can also create unsafe conditions around other people by increasing the risk of accidental contact, falling equipment, or flying debris. For your business, this could mean delays, medical costs, and lost revenue.

How you can prevent or reduce minor injuries:

- Use tools correctly and based on the manufacturer’s recommendations

- Wear appropriate gloves and protective equipment

- Keep tools organized and stored safely when not in use

- Provide training on proper tool use and job site safety

5. Electric shock

Working on metal pipes can pose a risk of electric shock, especially if the pipes are near electrical wiring or fixtures.

Electric shock can cause serious injury or even death for technicians. It also puts clients at risk if electrical systems are disturbed or damaged. For plumbing businesses, electrical accidents can result in severe liability and regulatory issues.

How you can prevent or reduce the risk of electric shock:

- Turn off electrical power in the work area before starting plumbing work

- Use insulated tools when working near electrical components

- Wear rubber-soled shoes to reduce conductivity

- Stay alert to nearby wiring and electrical fixtures during the job

6. Burns

Plumbers can sustain burns from hot water, steam lines, or power tools. That’s why it’s so important to always check the temperature of pipes and fixtures before handling them.

Burns can range from minor to severe and may require time away from work to heal. They can also cause damage to client property if hot systems are mishandled.

How you can prevent or reduce the risk of burns:

- Always check the temperature of pipes and fixtures before handling them

- Use heat-resistant gloves when working with hot water or steam lines

- Take extra precautions around equipment that generates heat

- Allow systems to cool when possible before starting work

7. Musculoskeletal injuries

Repetitive movements and working in awkward spaces can lead to musculoskeletal injuries, such as tendonitis or strains.

Over time, these injuries can cause chronic pain and limited movement. They can also prevent technicians from having mobility on certain jobs, limiting their ability to complete rigorous projects.

How to prevent or reduce musculoskeletal injuries:

- Practice proper lifting techniques, especially when handling heavy materials

- Use ergonomic tools designed to reduce strain

- Take regular breaks to stretch and rest muscles

- Implement plumbing hazard controls that support long-term physical health

Plumbing safety starts with awareness, best practices, and habits that are easy to follow. When you build these precautions into every job, you reduce risk, avoid costly setbacks, and set your business up for long-term success.

Originally published in April 2022. Last updated on January 7, 2026.